Keshun

KS-C101 CERAMIC TILE AND STONE ADHESIVE

KS-C101 ceramic tile and stone adhesives is used for indoor adhesion with tiles of high water absorption. Product is made of portland cements, fine aggregate and multi modifiying additives. It can be directly used after water mixing. KS-C101 is mainly applicable for tiles with which water absoption over 6%, offering good anti-slip performance and strong bonding.

- Environmental-friendly

- Superior workability

- Tiles no need to soaked in water

- Good anti-slip performance

- Rough flatness requirment to slab

- Strong bonding adhesion

- Suitable for tiles size ≤ 600×60

KS-C102 TILE ADHESIVE

KS-C102 tile adhesive is a powdery environmentally friendly ceramic tile adhesive specially developed for indoor pasting of ordinary glazed tiles (medium water absorption ceramic tiles). It is formulated from ordinary Portland cement, refined fine aggregates, polymers and various functional modifiers. It can be used directly by adding water and stirring. It is suitable for pasting tiles with a water absorption rate greater than 3%, and the tiles are not soaked in water before construction. It has the advantages of firm bonding and convenient use.

- Excellent construction performance, strong adhesion and firmer structure

- It can effectively reduce empty drums and environmental protection

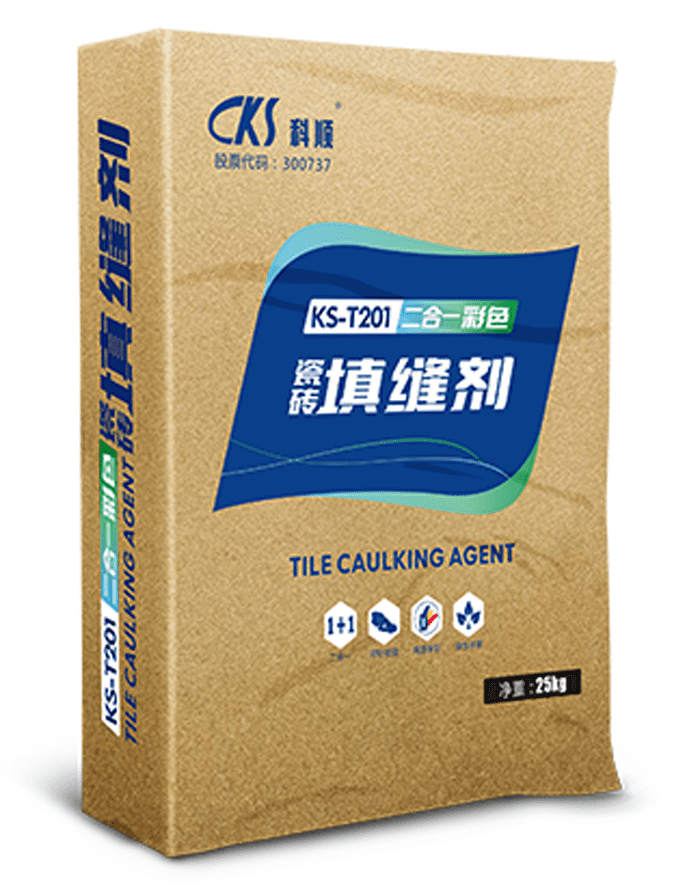

KS-T201 TILE CAULKING AGENT

KS-T201 two-in-one color tile caulking agent is a material formulated from high-quality cement, inorganic pigments, refined fillers, polymers and various functional modifiers. It is suitable for paving and caulking of indoor and outdoor walls and floors. The construction is fast and convenient, the product workability is good. It is suitable for paving and caulking of small paper tiles, ceramic mosaics and ceramic mosaic tiles with a joint width of 3~13mm or less.

- The integrated construction of pasting and caulking is convenient and quick in construction

- All inorganic pigment colors are used, which are safe and stable, and support design requirements for color matching

- It has good adhesion and is suitable for brick joints with a width of 3~13mm

- It has continuous adhesion, perfect safety and reliability, and good aging resistance.

Aquaflex KS-100X SPIDER SILK BIONIC FIBER WATERPROOF MORTAR

A new type of composite waterproof material developed by the technology of strengthening the cohesive force of high-strength fiber. The product is specially added with anti-cracking fiber, which can effectively enhance the comprehensive and anti-folding force of the coating, and can directly paste the tile. Spider silk” design concept: the product adds fiber reinforced materials, so that the product has strong adhesion; in the product of the extramural and comprehensive test, the product is broken by pressure, and the fiber material in the product plays a bonding role. The effect is similar to that of spider silk. As one of the selling points of this product, filamentous fiber can represent the characteristics of the product more, so it is named as spider silk.

- Flexural, compressive and impact resistant crushing

- Prevent tiles from falling off

- Enhanced service life

- Using high-strength fiberization cohesion technology, adding anti-cracking fiber can effectively enhance cohesion.

- The product has stronger adhesion, and the coating film is self-contained after it is dried, which makes the tile bond stronger.

- The product strength rises fast, making the waterproof coating stronger, effectively preventing the brick removal phenomenon caused by the falling off of the waterproof layer.

Aquacoat KS-929 SINGLE COMPONENT, MOISTURE CURED, POLYURETHANE WATERPROOF COATING

Aquacoat KS-929 single component polyurethane coating is moisture-cured high polymer waterproof coating. It can react with the moisture in the air and form a non-toxic and high elastic waterproof film. It is a new type of environmentally-friendly waterproof coating.

- Packed in one component and ready to use. It avoids the quality instability induced by the inappropriate compounding of two or three components

- The performance is stable. It possesses the property of aging-resistance, acid and alkali resistance, fatigue resistance as well as high and low temperature resistance

- Environmentally-friendly

- Good levelling property, simple construction. After coating, it will react with moisture in the air and cure, forming a compact, seamless, tough and high elastic waterproof film

- It can be compounded with high polymer membrane to form a compound waterproof system

Aquaseal KS-906 SINGLE-COMPONENT ELASTOMERIC ACRYLIC WATERPROOF COATING

Aquaseal KS-906 single-component elastomeric acrylic waterproof coating is one component water-based environment friendly polymer coating, which is made up of acrylic ester and many polymer emulsions. It is a kind of onecomponent waterborne environmental polymer waterproof coating material. Environmental protection water-based formula. This material can be applied at unexposed roof. KS-906 enjoy great popularity by customers for its simple construction, materials is widely used in concrete, metal roofing, old roof repair, indoor waterproof, etc.

- Free of pollution, non-toxic, environment friendly.

- Ready to use, it is suitable for engineering and home waterproofing

- Good adhesion, it can be applied on wet or dry substrate

- Good water resistance and tensile property, high elasticity and low temperature flexibility

W102 ACRYLIC ACID HIGH ELASTICITY WATERPROOF COATING

Acrylic acid high elasticity waterproof coating using imported pure acrylic latex as raw material, adding high quality additives and quality pigments, refined form a high-performance roofing coating. Product W102 can be used as primer& finish coating, applied with the W801 high strength woven polyester fabric to use, combined with all kinds of metal roofing or the concrete substrate surface to form a robust integrated composite waterproof coating.

- Environmentally friendly water-based coating, non-toxic, no construction and environmental safety risks

- Excellent flexibility and fatigue resistance, can adapt to the metal roof stretching deformation.

- Excellent stain resistance and weather resistance, reduce the maintenance and lower maintenance costs.

- Excellent UV- resistant and heat reflection performance

- Strong adhesion with metal, not falling, effective protect metal roof.

- Coating working well from -30 ℃to 90 ℃ temperature, function in all kinds of harsh environment test

- Open bucket can be used, construction is simple and convenient

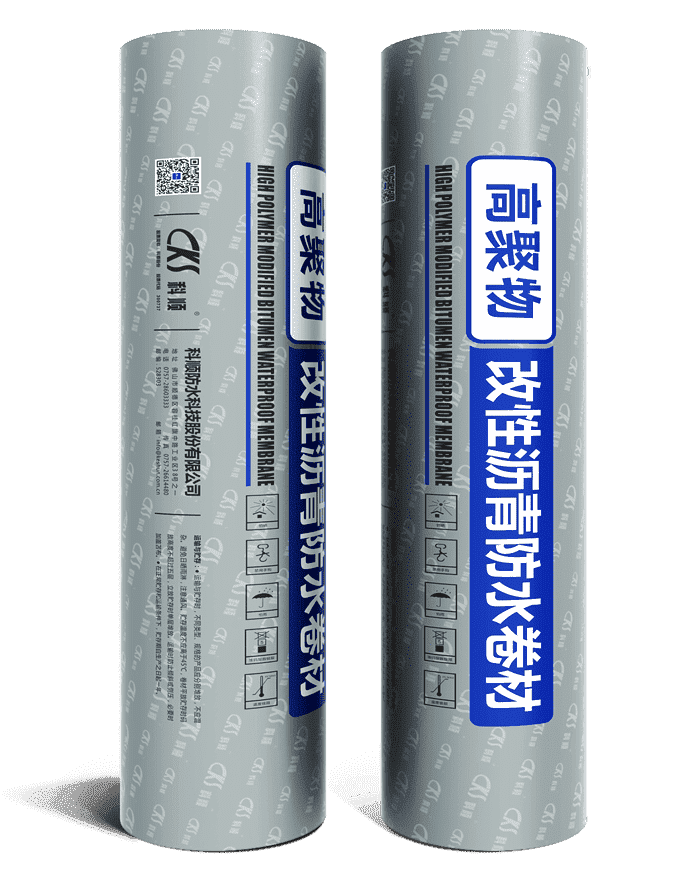

Aquatorch SBS Elastomer Modified Bitumen Waterproof Membrane

SBS Elastomer modified bitumen waterproof membrane is based on bitumen then added styrene, butadiene, styrene, TPE as modified materials, with special process to compound high polymer modified bitumen.

- Excellent low temperature performance, especially suitable for cold area application

- Good weather resistance, tensile property, high elongation, wear resistance and excellent workability

Aquathene APF-3000 Self-Adhesive Membrane with Cross Laminated Film

Aquathene APF-3000 pressure sensitive adhesive high polymer membrane, a patent product researched and developed by Keshun, is a high-performance membrane compounded by special technique. The structure of strong overlapped double-layer film plus vertical and horizontal mesh make the performance of tensile strength, dimensional stability, heat stability largely improved.

The adoption of patent wet-applied construction technique makes the PSA of the membrane crosslink chemically with the cement slurry, which form a powerful waterproof “skin” on the substrate. The “skin” will never separate from the substrate which make sure of the durability of the waterproof course and non-water channeling.

- Dimensional Stability, Tear Resistance Softness, Puncture Resistance

- Good Balance of High Elongation and Strong Tensile-Resistance

- Big improvement of thermostability

Aquaprufe TPO Waterproof Membrane

Aquaprufe Thermoplastic polyolefin (TPO) membrane is a type of polymer waterproof material based on polypropylene (PP) and rubber, prepared by existing technique. It is recycling throughout its service life (from its production till the end of its service life). There is no chlorine, heavy metal nor elements harmful to the roots and it is environmentally friendly.

- Excellent weather resistance, aging resistance, tensile strength and elongation

- Operation can be done on wet substrate.\

- Directly expose to the weather conditions without any protective layer. Simple construction. No contamination

- Repeat welding is possible

- White color TPO to increase reflection of sun rays

Aquathene APF-405 Self-adhesive Polymer Modified Bitumen Waterproof Membrane

APF-405 (PET-AI) Waterproof membrane utilized aluminized Mylar film as surface reinforcing material, covered with asphalt adhesive material which contains active agent rubber.

APF-405 can be used directly with polymer cement mortar in the construction (wet applied method), but also can be used according to the traditional construction method (dry applied), so as to meet the different needs of projects.

This product is especially suitable for the continuous construction of waterproof engineering design, when the construction period is long, and the exposure time of the membrane also is long, the component of APF-405 can function to reduce fold and the drum phenomenon of the materials.

- Strong bonding property

- Good tensile strength

- Excellent waterproof performance

- High reflectivity of sunshine

- Can prolong the service life of membrane

- Can reduce the indoor temperature of the building

Aquaprufe APF-C PRE-APPLIED, HDPE, FULLY BONDED MEMBRANE (SAND FINISH)

Aquaprufe APF-C pre-applied, fully bonded HDPE membrane (sand finish) consists of multilayer composite waterproofing material for superior waterproofing performance, including a layer of high-density PE film, self-adhesive polymer layer and a unique particulate layer. Aquaprufe APF-C pre-applied, fully bonded HDPE membrane (sand finish) can be installed on uniform and regular concrete blinding, compacted sand-stone cushion for waterproofing of below ground surfaces and is also used for waterproofing of confined surfaces or blind side waterproofing. Aquaprufe APF-C pre-applied, fully bonded HDPE membrane (sand finish) is designed so as to bond fully and permanently with poured concrete against it after placing and tying reinforcement.

Forms a unique integral seal to concrete poured against it. This prevents lateral water migration and Waterproofing performance is unaffected by ground settlement beneath slabs. Fully-bonded watertight selvedge laps and detailing Provides complete barrier to water, moisture and gas. physically isolates the structure from the surrounding ground. Zero permeance to moisture.

- Solar reflective, being white in colour thereby reduce temperature gain.

- Very easy and efficient to install, does not require primer or fillet.

- Easy to install on permanent formwork – allowing efficient use of confined sites.

- Self protecting–reinforcement can start immediately after installation

- Unaffected by wet conditions-cannot activate prematurely.

- Being HDPE, highly chemically resistant, effective in all types of soils and waters – protects structure from chlorides, sulphates and aggressive ground conditions.

KS-302 BASE MIXTURE FOR BITUMINOUS MEMBRANE

Water-based base treatment agent for bituminous membrane is made of polymer modified emulsified bitumen which is mainly used for the base treatment before the construction of waterproof membrane in order to improved the bonding performance between membrane and base material, and has the function of sealing the capillary pores of the base of mortar and blocking water or liquid penetration.

Keshun – Contact Sales Team

For Upper Myanmar

For Lower Myanmar

Latest News

-

ကြံ့နှစ်ကောင် အသင့်ဖျော်ကွန်ကရစ် မိသားစု မိတ်ဆုံစားပွဲ နှစ်နှစ်ပြည့် အမှတ်တရပုံရိပ်များ21 Feb 2024

-

“အားလုံးအတူ ပျော်ရွှင် ကော့သောင်း - ညောင်းဦးဖီး - ရနောင်း “ ခရီးစဉ် …. 😍👏🏻👏🏻16 Jan 2024

-

ရခိုင်ပြည်နယ် မိုခါမုန်တိုင်းဒဏ်သင့် ပြည်သူများအတွက် အလှူငွေ ပေးအပ်ခြင်း16 Jan 2024

-

ပဲခူးတိုင်း၊ ပဲခူးမြို့နယ်တွင် ပဲခူးမြစ် ရေကြီးရေလျှံခြင်းနှင့် မိုးသည်းထန်စွာရွာ သွန်း သဖြင့် ရေကြီးမှုများ ကြုံတွေ့နေရပြီး ပိတ်မိနေသည့် ပြည်သူ များ၊ ရေကြီးမှုကြောင့် စားဝတ်နေရေး အခက်အခဲဖြစ်နေသည့် ပြည်သူများရှိနေပြီး အကူအညီများ အရေးပေါ် လိုအပ်နေကြောင်း ကြားသိရတဲ့အပေါ် များစွာစိတ်မကောင်းဖြစ်ရပါတယ် ….16 Jan 2024

Contact Us

Mandalay Head Office

- No. (E-1 to 10), 107th Street, Between 64th & 65th Street, Chanmyatharzi Township, Mandalay, Myanmar

Yangon Branch Office

- No. (272), Min Gyi Road, East Ywarma Ward, Insein Township, Yangon, Myanmar